Beverage Conveyor Belts: A New Unit from Comac

Discover the new conveyor belt unit from Comac for the beverage industry! Whether it’s bottles, cans, or kegs, our custom solutions will allow you to optimize your production processes and obtain an even more complete packaging line!

In this article:

- New beverage conveyor belts from Comac

- All the features of our conveyor belts

- How to obtain custom conveyor belts

Beverage conveyor belts from Comac

Beverage industry conveyor belts are not simply a way to connect different machines during the packaging process but also a key to obtain a smoother, faster, and more efficient production process.

Comac knows it well. That’s why we brought a brand new unit to life – exclusively dedicated to conveyor belts – which analyzes every single layout in order to design and create belts that are perfectly compatible with your packaging line.

Our beverage conveyor belts can be straight or curved and have different lengths. They’re ideal not only to handle bottles (both glass and PET) but also cans and kegs.

Therefore, these belts are quite versatile and able to fully meet any internal handling needs. At the same time, they help limit the systems’ operating and maintenance costs.

Comac offers a wide range of conveyor chains with their respective accessories, as well as the possibility to manufacture stainless steel hulls and structures guaranteeing the utmost standards of safety and hygiene.

Specifically, our available solutions feature:

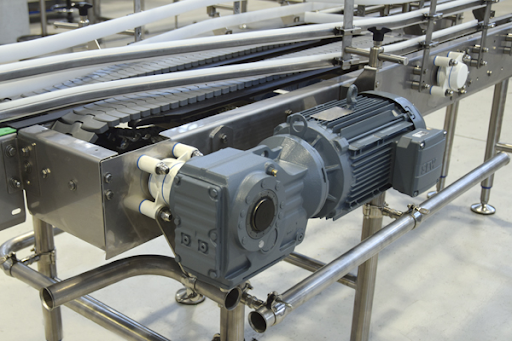

- The most suitable sizing of the gearmotor group with high-efficiency motors

- The reduction of container sliding on chains in case of accumulation, due to the use of specific software – resulting in energy saving

Lastly, for pre-existing layouts, Comac is able to manufacture compatible conveyor belts through an effective revamping of old systems, in order to perfectly readjust them to comply with the current regulations.

All the features of conveyor belts

Conveyor belts from Comac are custom-designed to meet the different production requirements of our customers.

Due to the high versatility that characterizes them, choosing among a vast range of shapes and sizes is possible, allowing to safely transport any type of container: bottles, cans, and kegs.

Specifically, our beverage conveyor belts feature:

- AISI 304 stainless steel structures and components

- Possibility to integrate belts on pre-existing lines

- A modular structure specifically suitable for handling optimization

- Programming by PLC control panel

- Possibility to use belts with different friction coefficients (high, medium, low)

- Simple and quick changeover

- The presence of an automatic lubrication system either wet (water and soap) or dry (synthetic), which not only enhances the proper functioning of the belt but also limits noises and cleaning operations.

Find out more about our beverage industry conveyor belts!

Find how to obtain custom conveyor belts

As already mentioned, Comac manufactures beverage industry conveyor belts according to the production requirements of its customers.

With its specific design department, in fact, Comac is able to set a clear and precise feasibility study and then proceed to offer adequate solutions that meet these requirements – complete with a layout and technical descriptions.

Through this procedure, promptly handling and solving any kind of requirements our customers have is certainly possible.

Once the design stage is complete, the manufacturing of the conveyor belts is carried out.

The final step is the belt assembly and installation at the customer’s premises. As with every processing stage, this phase is performed by specialized and skilled staff.

Do you wish to know more about our beverage industry conveyor belts?